Warmly welcome new and old customers to call and write us to negotiate business.

E-mail : sales1@yetbearing.com

Thin Section Bearings

We usually use bearing steel (GCr15), but many manufacturers only use softer carbon steel materials, so our bearings have higher hardness and longer service life.

Category:

Email: sales1@yetbearing.com

WhatsApp: +8619100655323

Message

Product Description

Product introduction

material

We usually use bearing steel (GCr15), but many manufacturers only use softer carbon steel materials, so our bearings have higher hardness and longer service life.

Heat treatment

We have our own heat treatment plant and do not need to be outsourced. We use a slower speed and more stable temperature to effectively control the steel and increase the toughness and life of the steel.

Other small-scale bearing companies usually need to outsource. Many outsourcing factories only strengthen the hardness of the bearing surface due to cost factors, but the hardness inside is not enough, which is the reason why many bad bearings are easy to crack.

Precision

Our bearings can be controlled at a height accuracy of 0~-0.004mm, fast speed and smoothness.

Multiple grinding process

We grind the bearing many times, but others may grind it only once, so the chamfer of our bearing is very smooth.

In conclusion

We use high-quality materials and multiple grinding processes, so our bearings have the characteristics of high speed, low noise, high precision and long life.

|

Products Name |

Thin Section Bearings |

|

Model |

6816 6817 6818 6819 6820 6821 6822 6824 6826 6828 6830 6832 6834 6836 6838 6840 2RS ZZ |

|

Size (d*D*B) |

80mm~200mm |

|

Material |

Gcr15 |

|

Tolerance code |

ABEC-1, ABEC-3, ABEC-5, ABEC-7 |

|

Vibration level |

V4, V3, V2, V1 |

|

Radial play |

C0, C2, C3, C4,C5 |

|

Retainer |

Steel or nylon |

|

Feature |

Smooth, low noise, good quality, long life,resistance to wear, |

|

Row Number |

Single row |

|

Quality Standard |

ISO9001:2000 standard |

|

Application |

Auto, tractor, machine too, electric machine, water pump, agricultural |

|

Delivery Lead Time |

Normally 3-15days |

|

Packing |

Ours or according to customer's requirements |

|

Payment Terms |

A:100% TT |

|

OEM Welcome |

Technic drawings or samples needed |

Factory Appearance

Packing and shipping

Production Process

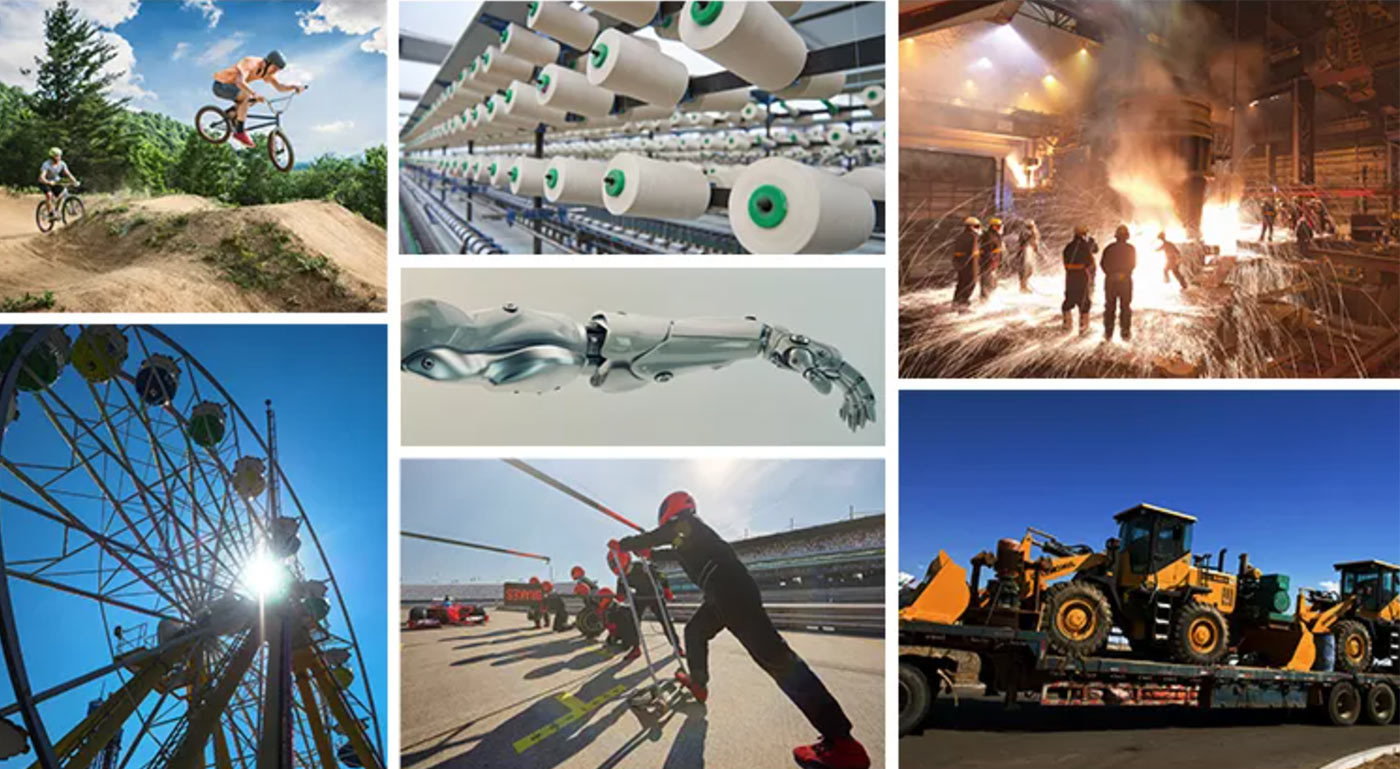

Application areas

FAQ

Q: How long is your delivery time?

Q: How to package?

Q: Are we traders or manufacturers?

Q: I want a specific size or color. OK?

MESSAGE